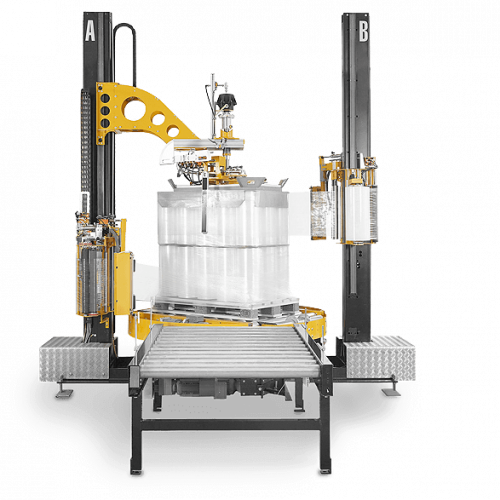

A pallet wrapping machine from STREMA®

A pallet wrapping machine ensures that all the products you manufacture as a company arrive at your customer reliably and damage-free. In order to achieve this result, your loads have to meet certain requirements. We have listed these requirements for you.

- The load must be well stacked. Inclined on a pallet or protruding parts outside the pallet are a bad starting point.

- The load must be packed well in succession. A number of parameters determine this.

- Wrapping loads on pallets with a pallet wrapping machine is the most commonly used and cheapest form of pallet packaging. There are two important factors for achieving optimum packaging: Constant quality of the stretch film & Pallet wrapping machine that is able to get the most out of the stretch film. Loads are packed stably and efficiently at low material costs.

We are happy to share our knowledge about our pallet wrapping machines with you!

STREMA® has been developing and manufacturing advanced pallet wrapping machines since 1981. Our customers demand ever-higher packaging requirements, stable packaging at minimal packaging material costs. This requires specialist knowledge. STREMA® has this knowledge in-house. We are happy to share this knowledge with you!

De rekwikkelfolie wordt opgerekt in de palletwikkelmachine

Products are often stacked on wooden or plastic pallets. These pallets are the carriers of the loads. Loads often consist of loose products such as boxes, trays or bags. These cannot be transported without packaging material. This packaging material protects these loads during transport against sliding and damage. Damaged loads cause a lot of loss. Unnecessary costs and dissatisfied customers are the result. Packing your loose products is the only way to deliver your cargo to the customer without damage. One of the most common, but also the most efficient way of packaging is wrapping a load with stretch film.

Stretch wrapping film, as the name suggests, can be stretched up to 350%. 1 metre of film from the wrapping film reel is stretched in the pallet wrapping machine up to 4.5 metres before being wrapped around the load. Stretching the film improves the film’s properties, more “bundling power”, and also leads to considerable savings in film consumption. In addition, different layers adhere to each other during the wrapping process due to the adhesive layer that the stretch wrapping film contains. When you have your load wrapped with stretch wrap film, you are almost certain of a stable packaging with sufficient “bundling force” to the load. Even the top of your load can be protected with film!

Not only does wrapping provide reliable packaging for the transport of your products, it also protects your products from moisture and dust. Black stretch wrap film is often used for theft sensitive products. This keeps your products out of sight.

We supply various stretch wrapping machines

STREMA® has various stretch wrapping machines in its package. When you have outgrown manual wrapping, you can choose the next step. Semi-automatic stretch wrapping. Or fully automatic stretch wrapping when you don’t want to have to worry about it anymore.

Manual wrapping

Manual wrapping is often used with very low capacities, a few pallets per day. Manual wrapping is labour intensive and not ergonomic. This method also has a low film efficiency and a highly variable wrapping pattern.

Semi-automatic stretch wrapping machines

From a few pallets per hour, the capacity becomes too high to go for manual wrapping. Semi-automatic pallet machines are then the solution. These machines already achieve a capacity of 20-25 pallets per hour. Because the wrapping cycle is fully automated, every load has the same wrapping pattern. In addition, these stretch wrapping machines have a pre-stretch system. The pre-stretch system stretches the wrapping film to the desired pre-stretch percentage.

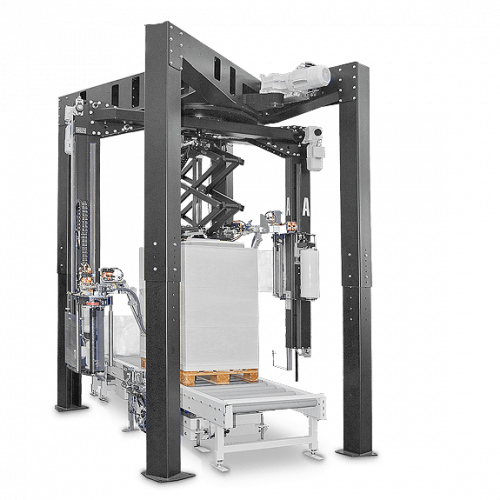

Fully automatic stretch wrapping machines

If you want a fully automated process, a fully automatic stretch wrapping machine is the solution. Loads are packed fully automatically without the intervention of an operator. Operators only need to replace a film roll from time to time. These stretch wrapping machines have several wrapping programs that can be set. The different loads can be processed together, the stretch wrapping machine chooses the right program for the right load. In this way, the stretch wrapping machine automatically adapts to different loads.

Why buy a pallet wrapping machine from STREMA®?

STREMA® has been an expert on the market of pallet wrapping machines since 1981. It has its own development department and production facilities. Many milestones have now been reached. The development continues and we continue to grow slowly.

Constant high quality

STREMA® stands for quality! Our pallet wrapping machines are developed and built in Germany with mostly German quality components, the so-called A-components. These components guarantee a long service life and are widely available. As a result, you are not completely dependent on STREMA®. You are free in your purchase choice. This saves costs..

User-friendly pallet wrapping machines with a perfect result

Our fully automatic pallet wrapping machines are all equipped with a twin-engine Pre-stretch system, a very simple film roll change, thanks to the SMART-Load system.

Thanks to the twin-engine Pre-stretch system, the pallet wrapping machines are perfectly adjustable and controllable. It is also easy to pack almost any desired load. Because a STREMA® pallet wrapping machine is able to get the most out of the wrapping film, your loads are efficiently packed at low packaging costs. For each load, the film’s end tail is permanently sealed against the previous wrap. Loose film tails do not longer exist.

Pallet transport systems and safety devices

Pallet conveyors and safety devices are necessary for fully automatic pallet wrapping machines. We can supply these with a system, including its controls. This is not a must, you can also use and/or control your own system.

Our products

Semiautomatic pallet wrapping machines

In our range of semi-automatic pallet wrapping machines we can offer you turntable or arm pallet wrapping machines. Depending on your wrapping requirements, a choice will be made for a turntable or arm pallet wrapping machine. If you opt for a simple operation without fuss, then the simple button panel is the solution. If you require more parameters and programs, we offer the pallet wrapping machine with a Touch Panel.

Fully automatic pallet wrapping machines

Our fully automatic pallet wrapping machines are also available in a turntable or arm version. We deliberately do not have ring wrappers in our package. With our pallet wrapping machines we can carry out all the possibilities of a ring wrapper at a lower cost. The capacities reach up to 150 pallets/hour. Banding, top, middle or bottom starting/stopping is one of the possibilities. Our pallet wrapping machines have a well thought-out and reliable concept and are therefore low-maintenance and have a long service life. All this results in a lower cost price per pallet.

Both the STREMA® arm and turntable pallet wrapping machines are made up of the same components. As a result, the operation of both types is the same. Fewer spare parts are also required in stock.

See here a fully automatic pallet wrapper in operation:

Working method STREMA®

At STREMA® we work according to a fixed pattern. From your choice of STREMA® to delivery to your door: with us, you know where you stand.

Once you have placed your order with us, our team will make a mechanical and electrical proposal. Following an agreement between the two parties, the installation will be taken into production in Germany. The pallet wrapping machine will be fully assembled and tested in the factory in Germany. At the end of this process there is a possibility that you will come and do the Factory Acceptance Test (FAT).

After the FAT, the installation will be dismantled and transported. The pallet wrapping machine will be assembled on location. Then the commissioning will take place. Finally, the operators and mechanics are trained before the commissioner returns home.