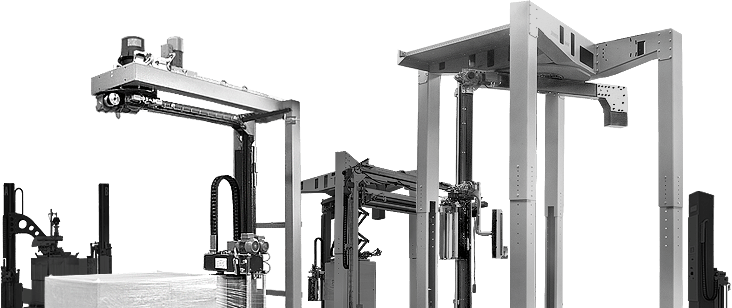

The STREMA® fully automatic rotary arm stretch wrappers are very robust machines, specially built for 24/7 use and fully equipped as standard.

All STREMA® fully automatic stretch wrappers are constructed as follows:

- Low-maintenance belt drives in combination with the smooth frequency-controlled movements contribute to a long service life and low maintenance costs

- All STREMA® fully automatic machines are equipped with a 2-motor driven pre-stretching system. Because both pre-stretching rollers each have their own frequency-controlled motor, they are fully infinitely variable from 50% to 400%. (1 meter of film becomes 5 meters)

- The pre-stretch can be accurately regulated at 5 different levels during the wrapping cycle. A sharp angle of a wooden pallet is NO longer decisive for the overall pre-stretch on load. The pre-stretch is reduced where needed and increased where possible

- The tension on the load is also precisely controlled during the wrapping process at 5 different levels by means of the electronic film tension control

- The standard equipped sealing unit melt the film end-tail over the full width of the film, the film remains the same thickness throughout during sealing. This will prevent loose film wisps

- Representative packaging is realized at low consumption costs. The right amount of film in the right place

- Simple transition to a different quality wrapping film, with a higher or lower pre-stretch percentage, without mechanical adjustments

- The SMART-Load System helps the operator change a wrapping film roll quickly, ergonomically and easily

- Simple operation by means of a clear Touch Panel

- STREMA® only uses A components. Such as Siemens PLC with Touch Panel, Festo pneumatics, SEW / Lenze motors, Lenze frequency inverters

- Very reliable energy transfer to the rotating parts by means of a fully enclosed IP54 slip ring. A proven concept

- The film consumption of each wrapped pallet can be read on the Touch Panel

- Naturally, all our machines comply with the applicable machine guidelines and are provided with the CE mark

In addition, the following options are available for all STREMA® fully automatic stretch wrappers:

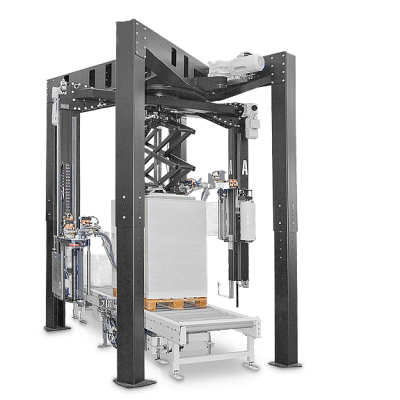

- Special hold down plate suitable for fragile loads. This hold down plate presses on the charges with little force. Fragile charges are additionally protected.

- Special load stability programs. The packaging requirements are getting higher, especially with the introduction of the EUMOS legislation.

- Making digital packaging data available. This gives you maximum control over your wrapping process.

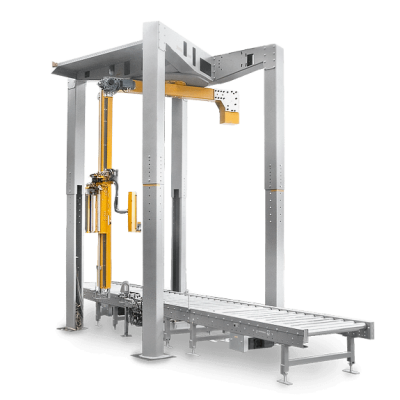

- Various transport systems. Depending on the direction of the pallet or the type of the pallet, different transport systems can be used, such as roller conveyors, chain conveyors or belts.

- Remote maintenance. The programmer can follow the wrapping process via an internet connection and, if necessary, make an adjustment. This saves a costly trip to the customer.

- Rainproof topsheet dispenser. Protects your load against moisture from above.

- Dustproof top sheet dispenser. Prevents pollution from above and makes theft more difficult.

- Safety features. Every fully automatic wrapper must be equipped with a safety cage with safety photocells.

Product Range

© 2025 Strema B.V. | Terms and Conditions | Disclaimer | Privacy declaration | Website developed by Sieronline