General characteristics STREMA® Pallet wrappers

STREMA® stretch wrappers originate in Hersbruck, Germany. The German “Gründlichkeit” philosophy has been in use since 1981.

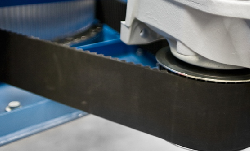

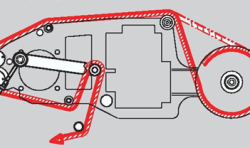

Toothed belt drive

By devoting all the knowledge and energy to the development and production of only pallet wrappers, we now have a whole range of further developed pallet wrappers that are aimed at the perfect packaging of your load and all work at low packaging costs. Many parts of the different types are identical, so fewer spare parts need to be stocked. Our stretch wrappers have ample adjustment options. Parts can be protected by means of different password levels. The robust STREMA® pallet stretch wrappers are extremely reliable. Many continuous companies preceded you. 24/7 that’s what the STREMA®’s are built for. And that for many years.

STREMA® introduced the double head technology in 1992. This made us a trendsetter. This dual head technology still offers you many benefits. This allows capacities of 150 pallets per hour to be achieved. Despite these capabilities, the speeds of the moving machine parts remain low. This makes the STREMA® double-head technology unique on the market of stretch wrappers. We use a completely closed slip ring (IP54) for the energy transfer to the rotating parts. Dirt and moisture are kept out. This very reliable energy transfer to the rotating parts makes the use of wireless technology completely unnecessary.

Very simple change of wrapping film thanks to the SMART LOAD SYSTEM®

STREMA® has all technical disciplines in-house. Our specialists take care of the assembly and start-up of the installation at your location. The training completes the installation. Operators as well as engineers are instructed on how to work with the wrapper. Several service support points take care of any first-line disruptions. A fast delivery of parts is guaranteed by the current stock. The used parts also have a long life span, are low maintenance and come with a full two-year warranty.

All our machines are modular and extremely flexible. Our machines also consist mainly of A-components, these are reliable, have a long service life and are generally available. All movements in the wrapper and possibly co-controlled transport systems can also be operated manually via the touch panel via the manual control functions. Naturally, the wrappers comply with the latest machine guidelines and are fully CE.

Full width sealing (500 mm)

Every STREMA® fully automatic stretch wrapper is equipped with a two-motor stepless adjustable pre-stretch system. This has many advantages. For example, any desired pre-stretch percentage can be made up to 400% (1 meter of stretch wrap film is stretched to 5 meters). The film tension on the load can also be stepless adjusted. In combination with the electronic control, the film tension on the corners of the load can be reduced. The different zones in the load may require a different pre-stretch percentage or tension to the load. By making good use of all these parameters, highly efficient batch packaging can be made with minimal film usage. A very simple film change system, the SMART-Load system® makes working with a STREMA® extremely simple and ergonomic. All operations and settings are done with a Touch Panel. The film consumption of each load is also displayed on this Touch Panel. This ensures better awareness of film consumption and thus packaging costs.

Many STREMA® stretch wrapping machines prove themselves daily in various industries. The film end tail is consistently sealed over its full width against the previous film layer, Full width sealing. Loose film ends are therefore a thing of the past. Very suitable for automatic warehouses and AGV transport systems.

See also www.strema.de