Pallet wrapper

A pallet wrapper is indispensable in most production companies. All products produced by production companies ultimately have to be transported to different distribution locations.

There are a number of criteria to get loads to the end station reliably and damage free:

- Loads must be well stacked. That means no projections or leaning stacks.

- Loads must be well packed. Sufficient stability and a good connection between pallet and load is required. However, it is important that pallets remain ‘open’ for further transport possibilities.

We are happy to share our knowledge of pallet wrappers with you!

Since 1981 STREMA® has been engaged in the development and production of advanced pallet wrappers. Our customers are setting increasingly higher packaging requirements, stable packaging at minimal packaging material costs. This requires specialist knowledge. STREMA® has this knowledge in-house. We are happy to share this knowledge with you!

Prevent transport damage with a pallet wrapper

Many loads are stacked on wooden or plastic pallets. These pallets serve as carriers for the loads. The load often consists of loose components, such as boxes, trays or bags. If these loads were to be transported unpackaged, there would be a lot of transport damage, which leads to loss and a bad name. In order to get these loads to the customer reliably and damage free, they need to be properly packed. The most common, efficient and economical form of pallet packaging is wrapping the loads with stretch wrapping film.

Stretch wrapping film is a film that is specially made to be supplied. Stretch wrapping film can sometimes be stretched up to 350%. Does that mean that in practice? From 1 metre of unstretched film 4.5 metres of stretched film is made. In addition, this film is provided with an adhesive layer. In this way the layers stick together during the wrapping process and form a whole.

The need for a pallet wrapper

Providing stretch wrapping film by a pallet wrapper has multiple purposes and multiple advantages. One goal is to make a stable packaging with sufficient ‘bundling force’ to the load. In addition, the force at the corners of the load must not be too high to prevent damage and corner crushes. If the load does not move sufficiently, the film acts like an elastic band and does not give the desired result. The film consumption also increases.

The film becomes thinner during dispensing, a film saving is thus realised. In addition, the film protects the load against moisture and dust. The top of the load can also be covered with a layer of film. Wrapping with another colour of film is also possible, black film is often used for theft sensitive products. The coloured films can also be stretched.

The application of stretch wrapping film with a stretch wrapper

Wrapping by hand, with a semi-automatic stretch wrapper or with a fully automatic stretch wrapper. All three variants are possible. We explain the options for you:

Manually

Often used for very low capacities or very erratic loads. The disadvantage is very variable wrapping patterns, not everything from the film is used. Heavy work and low capacity.

Semi-automatic stretch wrapper

A semi-automatic stretch wrapper is used when the capacity is too high to do everything by hand. A machine is often used from 5 pallets / hour. A machine always wraps in the same pattern. This gives a better packaging. The pre-stretching system ensures the correct dispensing of the film. With a semi-automatic pallet wrapper you are able to wrap up to 20-25 pallets/hour, also depending on the speed of the operator.

Fully automatic pallet wrapper

A fully automatic pallet wrapper is used when there are few operating personnel present. In addition, the capacities are often too high for a semi-automatic pallet wrapper. Fully automatic wrapping is applied from 10 pallets/hour.

The fully automatic pallet wrapper has several wrapping programs at its disposal. In case of a continuous flow of pallets, a programme can be provided per load. The process of this pallet wrapper is explained by means of an example:

Load A is light and requires few film wraps. Load B is heavy and requires many more wraps and also other film settings than load A. In this way different types of products can be packed together in the right way without the intervention of an operator. This makes fully automatic pallet handling labour extensive.

Why buy a stretch wrapper from STREMA®?

STREMA® has been developing and producing only stretch wrappers since 1981. Despite all the developments that are being made on this form of packaging, there is a lot of knowledge in house. We can tell you all about the products that STREMA® offers. STREMA® has reached many milestones over the years and the organization and turnover is still growing.

Consistently high quality stretch wrappers

All STREMA® machines are constructed from standard A-components, mostly German components. These components have a long service life. These are also available everywhere. You as a customer do not become dependent on a company. This is cost effective and keeps you flexible.

Perfect packaging at a low cost

Every STREMA® fully automatic stretch wrapper has a perfect, easily adjustable twin motor pre-stretch system. This means that almost any type of load can be properly packaged. The correct pre-stretch and correct tension to the load can also be realized at the correct position in the load. In this way, the wrapping film is optimally used and packaging costs remain low.

Sealing the film end tail is standard. This prevents loose strings. A very simple film roll change makes the operator’s life more pleasant. Various settings in the PLC, which can be operated via the clear Touch Panel, enable optimal packaging of your product for the lowest possible film usage.

Pallet transport systems and safety devices

These additional components can also be supplied by STREMA® together with the wrapping system. The total package can also be included in the control system.

The products of STREMA®

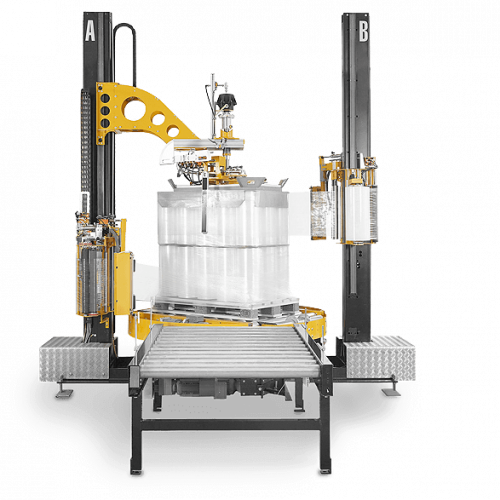

Semi automatic pallet wrappers

We have turntable pallet wrapping machines and arm pallet wrapping machines in our package. Depending on the application a turntable pallet wrapper or an arm pallet wrapper is chosen. If one single wrapping programme is sufficient, we opt for a very robust and simple button panel. If several programme choices are required, we opt for a Siemens Touch Panel.

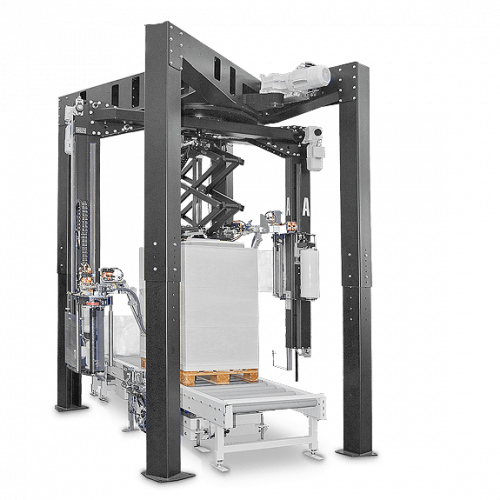

Fully automatic pallet wrappers

Also here we have turntable pallet wrappers and arm pallet wrappers in our package. We deliberately do not offer a ring wrapper. With our arm pallet wrapping machines we can perform all functions at least equal or higher capacity than a ring wrapper. Only then with all the advantages of an arm pallet wrapper compared to a ring wrapper.

Both the STREMA® fully automatic turntable pallet wrapping machines and the fully automatic arm pallet wrapping machines have many similar components. Also the operation of both types is the same. This makes it easier for the operating personnel. Fewer spare parts are also required in stock.

See a fully automatic stretch wrapper in operation here: