Maximum speed: 30 RPM

Capacity up to 90 pallets / hour

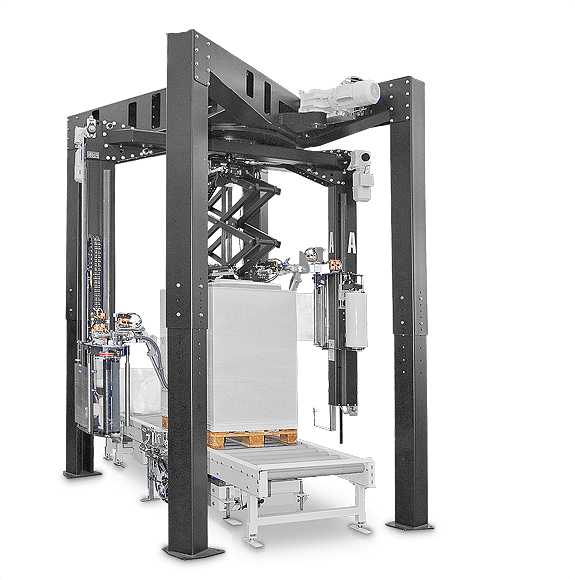

The A4000B II double-head arm wrapper does not differ much from the A4000 arm wrapper, but it does have a few extra components. The A4000B II has an extra mast with film carriage and thus achieves a capacity of up to 90 pallets per hour. And has double the amount of film on board, allowing longer runs without operator intervention. Each foil end tail is sealed over the full width, creating a perfect film finish.

The A4000B II can process up to 90 pallets per hour. Again, all movements are frequency controlled. The A4000B II is available with roller conveyor or chain conveyor and can be expanded with a top sheet dispenser (dust- or rainproof), a hold down plate or pallet lifting unit for a good connection between pallet and load.