News

STREMA® offers high capacities with little space for pallet wrapper

A common problem in a production environment. Certainly when it comes to existing construction. STREMA® recognises this problem and has come up with a solution. A turntable wrapper with two masts, rotation-driven hold down plate with film clamp. And two film carriages with twice as much film on board. Operation Pallet arrives on the turntable […]

STREMA® Variable wrapping distribution

With the variable wrapping distribution, the film is applied in the area on the load where it is needed. For example when wrapping PET bottles. The “buckling point” lies between the first and second layer. The buckling can be prevented by applying extra film over the entire load, but this drastically increases the film consumption. […]

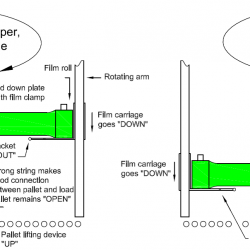

Separate wrapping of stacked pallets

Maximum efficiency Production environments are constantly looking for the maximum efficiency of the production line. The number of pallet positions is often limited. In case of many low pallets, it is possible to choose to stack these pallets immediately after palletising. The problem is then often that it becomes one whole after wrapping. Not with […]

Universal turntable wrapper

Recently STREMA® has installed a High Speed turntable wrapper. This wrapper can wrap the entire pallet as well as just lay a band (narrow band of film at the top). Customer’s products: The customer has two types of loads. The first has to be fully wrapped. The second has to remain open as much as […]

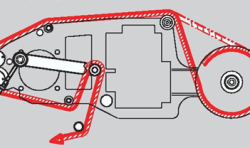

All types of film possible

STREMA® pallet wrappers can process all kinds of wrapping film. From thick to thin, from low to high stretch. Without having to convert the wrapper. Thanks to the two motors variable adjustable pre-stretch system / Duo Power Pre-Stretch System. On the Touch Panel, the Pre-Stretch values and the tension to the load values can be […]