Separate wrapping of stacked pallets

Maximum efficiency

Production environments are constantly looking for the maximum efficiency of the production line. The number of pallet positions is often limited. In case of many low pallets, it is possible to choose to stack these pallets immediately after palletising. The problem is then often that it becomes one whole after wrapping. Not with STREMA®. STREMA® has advanced solutions for wrapping stacked pallets separately.

Customer’s products:/strong>

The customer has two types of loads.

Pallets up to a height of 3,000 mm which have to be fully wrapped.

Two pallets on top of each other which have to be wrapped separately from each other. Both pallets can have different heights. For example, the upper pallet may be lower than the bottom one.

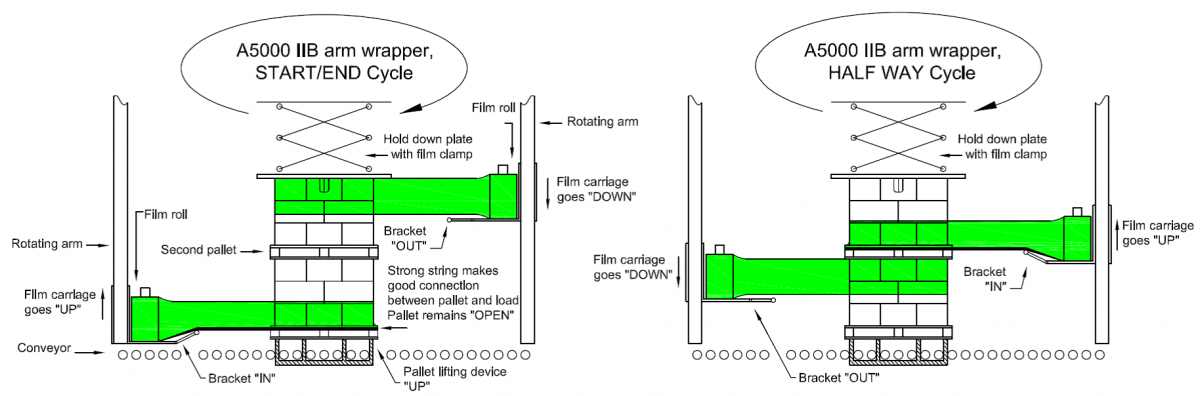

The stacked pallet must also have a good connection to the load and must remain “open” to the forks of the forklift truck.

Customer request:

One wrapper who can do both. Loads are mixed, up to a maximum of 80 pallets/hour.

STREMA® has the solution:

A double-head A5000 arm wrapper. In combination with a height measuring system. The measuring system determines where the pallet of the upper load is located. This information is used to select the correct wrapping programme. One film head starts at the top of the load, the other at the bottom of the load. Both go up to the middle of the pallet. For both the bottom and top load, the openings of the pallet are kept free of film. In both cases the film is made into a rope in order to achieve a good connection. Stacked pallets, separate wrapping is realised.